A Guide to Life Cycle Thinking

Absolutely everything that is created goes through a series of life cycle stages, from material extraction through to end of life. The scientific process of understanding what impacts occur as a result of the materials that move through our economy is called Life Cycle Assessment (or analysis, depends what country you are in).

LCA, as it is known in the scientific community, is a complex, deeply detailed process of breaking down all of the inputs that go into making something exist and looking at the outputs that occur as a result. These flows are measured against many (over 90) different impact categories that are linked to ecosystem health, from the obvious ones (such as carbon emissions and global warming potential) to the important but lesser known ones (such as eutrophication of waterways, human toxicity and ozone-depleting potential).

A quick introduction to LCA

LCA started in the 60’s but really was born as a reputable scientific process in the 1990’s after big players in the food and beverage industry needing to gain more detailed understanding of the impacts of their product packaging led to concerns over the use of the LCA information as marketing rather than decision-making tools. This resulted in the development of International standard ISO 14040, which governs LCA practice and lays the groundwork for what is considered a good assessment and what is a bit dodgy.

Nowadays, scientists, designers, and engineers have helped build the life cycle community into a thriving knowledge bank of cause and effect relationships between the industrial systems and the environment.

It’s important to acknowledge that it is complicated to do a LCA, and in many cases, is best left to the experts. Although it is by far one of the most effective tools we have to investigate the impacts that actions in the economy have on the planet, it also requires years of research and experience to be good at life cycle assessment. There are, of course, opportunities to conduct “quick and dirty” streamlined LCAs, but these shouldn't be published — they are more like ‘back of the envelope’ calculations that help to inform decision making.

Essentially, all life cycle assessments should be done by a skilled practitioner, mainly due to the datasets. The effectiveness of this type of study is based on two main things: the defined goal and scope of the study and the quality of the data that is used to assess the impacts. The data is often hard to get, as many companies keep their processes under lock and key.

But all of this research and information helps to build the capacity for a thinking tool that anyone can apply to explore the way products and materials impact the planet and people. This is life cycle thinking.

Key ingredients to life cycle thinking

This type of thinking requires clear framing and the ability to articulate what you are exploring, why and how you will do it so that there is clarity and transparency. This is why LCAs have a clear goal of the study and scope for the assessment, which allows for a system boundary to be established.

A systems boundary involves defining what you will explore and what you will not.

The ‘goal and scope’ is the framing that the study is done through. For example, if you had a study that only compared the impacts of a large family restaurant chain inside the restaurant walls (such as cooking and waste) and ignored the meat production, packaging and all other inputs needed to function as a food provider, then the study would not be a proper LCA, as it needs to cover the full scope of delivering the products to the customer.

LCAs are all about functional units — what you have to do in order to get the functionality — and you can’t assume that things like beef just appear out of thin air. In order to make a hamburger, you have to cut down trees, build a factory farm, grow and water feed for cows, raise the cows, kill them, and then process the meat along with all the other stages of transport, packaging, and cooking before you get to selling a hamburger to a customer. All of these activities require inputs — such as energy, water and of course cows — and thus have outputs, including waste and emissions along with the desired raw product. And all of these have impacts on the environment.

Data is also a crucial component with the outcomes often being as good as the data that is used for the assessment. When looking at a study, consider who conducted it, where the data has come from, and what the goal and scope is (this is always outlined in a LCA). Check for vested interests of the commissioner and what the functional unit that was used for comparisons was. Other things, like how old it is and what variables may not have been taken into account if it’s an older study, are also important factors in the quality of the data. For a primary researcher conducting a LCA, the degree of detail that they go into is pretty intense, and rightly should be as thorough as possible, as this results in more clarity of what’s going on across the entire life of a product rather than just one area.

LCAs should pretty much always be peer reviewed if the resulting information is to be publicly published. Here is a quick overview of what conducting a LCA entails, plus some details on the importance of the data used. Published LCAs enable the wider community to explore the findings and uncover new insights into industrial processes and the environmental impacts of everyday products and service delivery.

Why should you understand the full life cycle of your product?

First things first, if you are in any of the industries that make things (and there are a lot), then you should be drawing on LCA data as well as hiring experts to help you get a baseline understanding of the ecological impacts of what you produce to help you design to evolve these issues (check out this example by Levis).

In my opinion, LCA data should always be for the entire life of the core functional delivery of your product. Many companies only focus on their packaging, which is often a much lower impact arena than the actual product. The same can be said for the end-of-life focus that many design teams take when trying to create a so-called ‘eco product’. This narrow view often leads to uninformed decisions, increased environmental impacts, and unintended consequences (I go through this in my TED talk).

The best way to start any sustainability or circular economy adoption process is to start with a systems and life cycle thinking approach. It’s astonishing how many engineers, managers, and designers are none-the-wiser on what types and degrees of impacts their purchasing and production systems have on the core natural systems, air, water, land, and bio systems. This has to change if we are to transition to a circular and regenerative economy. We can’t guesstimate our way to sustainability, and this is why it is absolutely crucial that we have more life cycle approaches being adopted into all levels of decision making.

But to be fair, all of this is complex and complicated stuff. It has only been in the last few decades that science has really been deeply exploring natural systems, how they work, what impacts our actions have on them, and which ways we humans can live within the life-sustaining capacity of our wonderful planet. So, LCA is a very new phenomenon for many companies. It is, however, much more accessible today than it was 15 years ago when I first started out. There are way more experts, more university departments conducting studies, and much more data out there. The cost of conducting a LCA has decreased, and people can now access many summary studies online.

The main issue though is still a lack of knowledge within organizations to know the basics of how this works so they can hire the right people, write a good brief, know when to get a study done, and use this valuable information effectively in the product development process.

How can life cycle thinking help?

Life cycle thinking, as defined by the United Nations Life Cycle Initiative, is a “way of thinking that includes the economic, environmental, and social consequences of a product or process over its entire life.”

It is essentially the extracted thinking tool built off of the knowledge created by the scientific investigations of LCA. It does not require an expert with deep knowledge of the science — a basic level understanding is enough — but it is a thinking and decision support tool that expands the perspective of view from one dimension (such as waste or materials or transport) to the entire life of the product, all the way back to the extraction of raw materials and all the way into the future of potential end of life realities.

It’s like a magic mindset that provokes a producer to be thinking about cause and effect, consequences and potential, well before anything has happened, so that the decisions made ultimately allow for maximizing the environmental benefits of what is created.

How to apply a life cycle thinking approach

Learning new things is not usually that easy (try learning a new language as an adult), but what is not hard is the desire to learn something new. This becomes the foundation of activating the neuro-conditions for absorbing the new information. Something like life cycle thinking is the same. You need to want to discover the hidden world of how things are made in order to absorb the new thinking tools.

Here I will run through a quick outline of how to start to adopt a lifecycle approach. This is a critical part of the Disruptive Design Method and a companion tool to systems thinking.

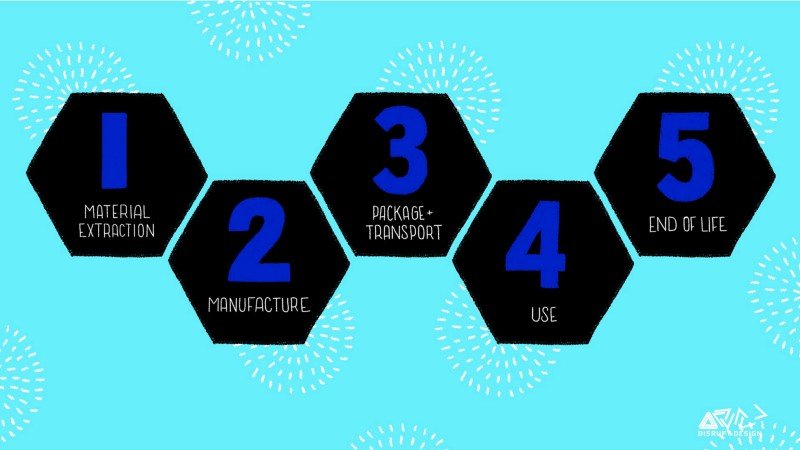

There are 5 Main Life Cycle Stages

Everything that is produced goes through these five main life cycle stages: materiel extraction, manufacturing. packaging and transportation, use and end of life. At each of these stages, there are inputs and outputs, flow-throughs, value losses, and potential gains. In life cycle thinking, we use these as a foundation for thinking through what needs to occur in order for something to be made.

1.Material Extraction: Everything comes from nature at some point, so all materials can be traced back to where and how they were extracted. Whether it’s stuff pulled out of the ground, cut down, or shorn off a sheep’s back, we need to change and often destroy ecosystems that would have otherwise been providing the service of clean air and water. So from a life cycle perspective, we always go back to what the land was being used for before we extracted the materials and then evaluate the method of extraction. Often, an ecosystem service was being provided for free by nature but is no longer able to do so as a result of the extraction. This about all the different ways we get materials from nature!

2. Manufacturing: This is where we take the extracted materials and transform them into usable base materials, products, and goods — the tree into wood chips that are then bleached and chemically irritated, heat rolled, and made into paper, which is then lined with a plastic film and turned into a coffee cup, for example. All activities in the manufacturing stage are accounted for, and the inputs and outputs (such as the input of energy and output of Co2, or the input of the tree and the outputs of sawdust and paper) are identified and explored for their positive and negative impacts to the biosphere. Manufacturing includes the manufacturing of extracted materials into usable ones and the possessing of multiple materials into usable goods.

3. Packaging and Transportation: This happens at every stage of the products life, and to be honest, is often where people assume the biggest ecological impacts occur— but it’s usually not when you compare all the activities across the entire life of the product. Packaging is a real conundrum, as it’s often overdone as well as made with materials that don’t fit back into nature well; however, sometimes the loss of the product is greater from a LCA perspective than the loss of the packaging. Like loose leaf salad greens: if packed in a plastic cushion bag, we often have way less product loss, which has a net ecological gain. Transport is much the same — sometimes it makes sense to transport things across the world rather than grow it locally if the climatic conditions do not allow for it (like tomatoes being grown in a hothouse with loads of energy inputs in a cold climate vs being shipped from a warmer location, the latter is often better when everything is taken into consideration).

4. Use Phase: This is where we buy the product, take it home, use it, maybe wash it, perhaps add extra things to it over its life, and then when it is no longer desired, functional, or fashionable, it moves on to the final stage of its life. The thing to identify in the use phase is if the products are ‘active’, meaning they have to be plugged in or washed, for example. This will mean that the use phase often dominates the life cycle impacts of these types of products, as it is the connection to a bigger system as a core requirement of its functioning that draws constant impacts. Products that are ‘passive’, meaning they don’t need any extra inputs throughout their life (like a chair or a book), often have lower use phase impacts and instead are dominated by manufacturing or material extraction (and of course, end of life).

5. End of Life: The end-of-life impacts vary dramatically based on the options that are available in the location and the way the product was designed. There are basically 4 main EoL options: landfill and littering (where we lose values from the system and create negative externalities), recycling with degrees of remanufacturing, reuse, repair, etc) and incineration (which replaces fossil fuel production, but does mean we lose all the materials from the system). Each has its own degree of impact and emotional triggers. People hate waste, and so assume that end of life is the bigger part of the product’s impacts, but in many cases, it’s often not the biggest. In saying this though, it’s incredibly important to know that all waste is a tragedy, and most humans design systems that lose value over time so we end up with built-in wastefulness through disposability. All EoL issues must be addressed at the start of the product life, not the end.

Inputs: These are the resources that are required in order for something to happen, such as a tree for wood or water to grow the tree. There are a bazillion different types of inputs, but think of anything needed to go in in order to get something out.

Outputs: These are the resulting things from the processing of the inputs, but positive and negative outputs in nature are the intended and unintended consequences of actions. So, water coming into a factory can help to break up the wood fibre of a tree to make paper, but then you have waste water contaminated with the chemicals used in the processing, which now needs to be treated in some way before reentering the natural environment. The other output from this is the wood pulp ready to be made into paper. The same applies with energy creating power and CO2.

Flow-throughs: Basically this is the way in which things flow through a system from the input to the output and the activities that occur through this. In systems thinking, we call this stocks and flows, and it results in feedbacks. In life cycle thinking, it helps to think about how we see things flow through the needed system in order to get to the desired outcome at each stage of the product’s life.

Impacts: Everything that is created requires something else to be changed, altered, destroyed, converted, etc. Actions result in reactions and consequences, and in life cycle thinking, we are concerned with the impacts of actions. If you make a decision to swap your packaging from one material to another, what are the resulting impacts across the life of the product, and how do you maximize the functional gain whilst minimizing the negative impacts to people, the planet, and the bottom line?

Life Cycle Thinking Tools

There are three main tools for life cycle thinking: mapping, research, and streamlined assessments.

The research part is where you explore and synthesize the existing LCA data on the materials, processes, and products that you are working with. This enables you to develop a broader and deeper understanding on inputs, impacts, and effects. The best way to do this is to go to Google scholar (a special part of google that only lets you access peer-reviewed papers) and search for life cycle assessments of whatever you’re researching. You can then read the abstracts and check for the conclusions across a variety of studies to see what the consensus is on a particular material or product. It does take a bit of time to get your head around the data and language, but be persistent and you will get it. It is extremely insightful to discover what the latest research is for your industry.

The mapping component allows you to uncover the hidden processes that go into making a product as well as to compare different functional units in order to achieve the set goal or outcome of the product. I explain in much more detail how to do this below.

Streamlined assessment tools are online tools like this and this (here is a study reviewing full LCA tools, and here is a list of streamlined tools which tend to use more basic data sets for quick and easy access). These streamlined tools have been developed to help run quick basic life cycle assessments of a product or material to help inform the design decisions and adjust the impacts of the product. Caveat: I worked on the development of one of the first ever streamlined online LCA tools over a decade ago called Greenfly. It was never commercialized (long, very painful story), but what I discovered through that work was that your assessment is only as good as the data set that’s behind the tool — so check it first and make sure that you are getting good data. There are integrations into CAD and stand alone tools you can use too.

What’s extremely important to know is that life cycle assessment is governed by an international standard, and you can’t make claims about environmental benefits of products unless you have a third party, peer-reviewed full LCA. Streamlined LCAs are design-decision support tools and should not be used for marketing purposes. The same applies to life cycle mapping; it’s a useful knowledge and capacity building tool, not a marketing one.

How to do a life cycle map

The purpose of LCT mapping is to explore and compare the impacts of the entire life of a product. You start by identifying all the processes, materials, inputs, and outputs that go into making something. This helps you get a much broader perspective of the impacts that result from the decisions you make. It’s a discovery tool that empowers more detailed reflection on cause and effect whilst also offering fascinating insights that can dramatically change the way you produce and deliver a product to market.

Simple life cycle mapping worksheet

Start by defining what you are going to explore, a product or material, and if you want to compare different things, then you must define the functional unit. A standard cup of hot liquid requires different material and physical properties than a cup of cold liquid. The articulation of the core and required functionality establishes the scope of what you are exploring.

If you were to look at a food product and compare the different modes of producing a single tomato, then you would compare that and look at the difference between a hothouse production to a natural system.

One you have defined the scope of your exploration, grab a blank piece of paper (or use the handy illustration above as a starter). You will be identifying all the different activities that occur across the main life cycle stages, starting with material extraction, identifying all the things that have to happen in order to get the raw materials out of nature. This can be quite detailed for complex products (a cell phone that has 50 different materials in it), but you have common knowledge and the internet to figure these things out!

For detailed projects, you may need to start by developing a Bill of Materials (BOM) that list all the different standard materials needed to make the product, and then draw links between how the material is made (in the manufacturing stage) and how it was extracted from nature.

Once you have a list of the main ingredients used, you can start to explore the other phases of the product’s life, such as product manufacturing. How are the extracted materials processed and transported around the world? What stages do they go through in order to go from raw to usable state? What inputs are required and what outputs come about as a result? For example, there are many different ways of transforming bamboo into a usable industrial material. If it’s used in a more natural way so as spoon, there are far less manufacturing stages than if it were being turned into a fabric, which often requires many chemical processes in order to do so. You can discover many of these things with a quick internet search to help build your knowledge bank on material processing.

After you have identified the materials and the activities from raw to usable states, start to build the map of the product’s manufacturing process. Here there are often loads of transporting and packaging activities to include.

Then you move onto the use phase, where you consider all the different use-case scenarios that are likely to occur. Is the product active or passive? What are the use phase inputs, such as water for washing or energy for charging? Try to calculate what the per functional unit use impact is, meaning if you want to get one cup of boiled water, how much energy is required for say an electric kettle, a stove top pot in electric and gas, or an instant water boiler? It’s here in the use phase that you will notice just how much the design decisions influence the impacts of the products during its usable life. Use phase can include the retail and sales environment as well, but the main impacts occur in the relationship between the design and the human interaction with this.

After use, map the potential end of life options and again draw links between the materials used and the most likely ways they would be discarded. You will find that the way things are assembled often directly impacts the way they are treated at end of life. For example, some cell phones are designed to lock the consumer out with special patented screw heads, yet they will have a warning about not disposing of the battery in the normal trash — but you can’t get into the phone to remove the battery!

I developed the diagram below to help you consider what the end of life options are, like recycling, reuse, or remanufacturing. You must consider a few factors here, such as what is the likely use case and and what is the variants of this. Not everyone will recycle, some percentage of products get lost through litter, and if a city doesn't offer recycling, then it won’t happen! Also be sure to check before you guess if something is actually recyclable (for example, paper cups are not, as they are lined with a plastic film that makes it very hard to get value out of the recycling process).

Mapping end of life (EoL) options in life cycle thinking

Once you have done all the other stages and get to end of life, you will start to see just how much the design of the product impacts the end of life options. Obviously the system wide impacts (such as availability of recycling and cultural norms) will also impact EoL, so consider all of these factors, add them to your thinking toolset, and you will be in a way more informed position around the whole of life impacts of actions we take in the economy.

The goal of life cycle mapping is to get a more comprehensive understanding of the entire life of the product and then use this to compare different functional deliveries for design changes that result in more effective products that have considered the full life cycle impacts. Get this right, and you are much closer to designing products that fit within the circular economy.

You can do quick maps that give you a basic perspective or spend a lot more time developing a very detailed understanding of all the inputs and outputs that go into making something exist in the world. Whatever way you approach this, do it and you will uncover a set of incredibly useful new insights that lead to a practice in circular and sustainable design.

Tips for developing a life cycle approach

Whenever starting anything new, there is always a learning curve. What starts off as alien in thinking can quickly become second nature. That is what the goal is with life cycle and systems thinking tools, that your brain starts to automatically think across the full life of things and go quickly into deeper thinking about the relationships, flow, and systems that make them up. Here are some useful tips to be mindful of:

Don’t get stuck in an end of life bias. For many people, when people see environmental problems, it’s common to automatically assume that it is waste that is the big issue since we see the impacts of it so often in our lives. But there are so many cases where waste is the lower impact area than say the use phase (as is the case with technology and clothes). So focusing on the end of life eliminates the intent to redesign the products service from the start.

Dissect and rebuild. The goal of thinking through the entire life is to see the hidden costs and to break the processes down into individual parts so that the full picture can be put back together again in a more sustainable way.

Know that the answer to any LCA question is ‘it depends’. This used to drive me and many people nuts when working in LCA. Any expert will often respond to a question about what is better, x vs y, and they would say, “It depends!” This is because it really does depend on a number of factors such as energy mix, how materials are processed in different ways, or the end of life scenarios. There is no one hard and fast rule. Things produced in a country with a greener energy mix will almost always look better than products manufactured in countries with coal power, for example.

The amount of material is a big contributor to impacts. Weight often increases impacts, and that’s why we say ‘doing more with less’ is the key starter step to sustainable design, as the more you have of a material, the more is needed to be extracted, and the more of everything across its life that is used. Here is an example video with cups.

You can only compare functional equivalency. Things are designed to achieve a set function. A cup holds x amount of hot liquid, and if you tried to compare products that achieve a different level or type of functionality, then you will get squid data. Often when you compare a ton of one raw material to another, the data will be completely different from when you compare a product made from the same materials. This is the case with the plastic vs paper bags. Basically you need more paper to achieve the functional unit of carrying groceries home (only reason bags exist), and thus the overall impact of using a paper bag is worse as you need 4 to 10 times more material than a plastic bag. When you look across the life and take into consideration all of the impacts of making paper, this material property difference stacks up to have a bigger impact than the thin plastic alternation. I explain all of this in my TED talk here.

Life cycle approaches traditionally don’t include the social aspects. The scientific approach predominantly has looked at impacts to the biosphere, but there is a growing movement around social LCA and the development of impact indicators, which explain the impacts to society and humans directly associated with the product across its life. I personally think that social aspects can be easily included in the LCT approach since it is about researching and exploring the conditions of human labor and the environmental consequences to local communities.

We still don’t have many of the answers we need to make better decisions. The fields of sciences that explore the impacts that humans have on the planet, or even how the environment works, are all relatively new fields of study. LCA data is 25 years old, and we have surmounted a wealth of knowledge but also uncovered the extent of our collective ignorance to how natural and industrial systems work. That’s why we always need more work and research into these questions of cause and effect as a result of economic activity.

Everything comes from nature at some point. No matter how ‘synthetic’ something is, the raw materials needed to make it came from a natural system and eventually will have to return to one. That means, everything we create must be made with the intent to be part of a circular system that sustains and even regenerates the planet.

There are always tradoffs that need to be made. It’s the hard thing for many people to rationalize — the trade offs of impacts at one stage of the life in order to get a much more significant gain somewhere else. It can feel counterintuitive and frustrating, but we need to make change and push at the boundaries of how we produce and consume things, so this means understanding the complexity of the systems that we are existing within.

Here are a few other tools and resources to help you on your knowledge- building journey.

— — — — — — — — — — — — — — — — — — — — — — -

For more systems and life cycle thinking, check out all of my online classes at the UnSchools Online >

Illustrations by Emma Segal